The READi process converts high-molecular feedstocks into liquid fuels in the middle and short-chain range.

Simultaneously, heteroatoms such as oxygen, sulfur, and nitrogen are reduced or removed. The READi process combines both “ Reaction” and “Distillation”. Reaction means thermochemical decomposition of the feedstock molecules in a solvolytic self-regenerating heavy oil phase.

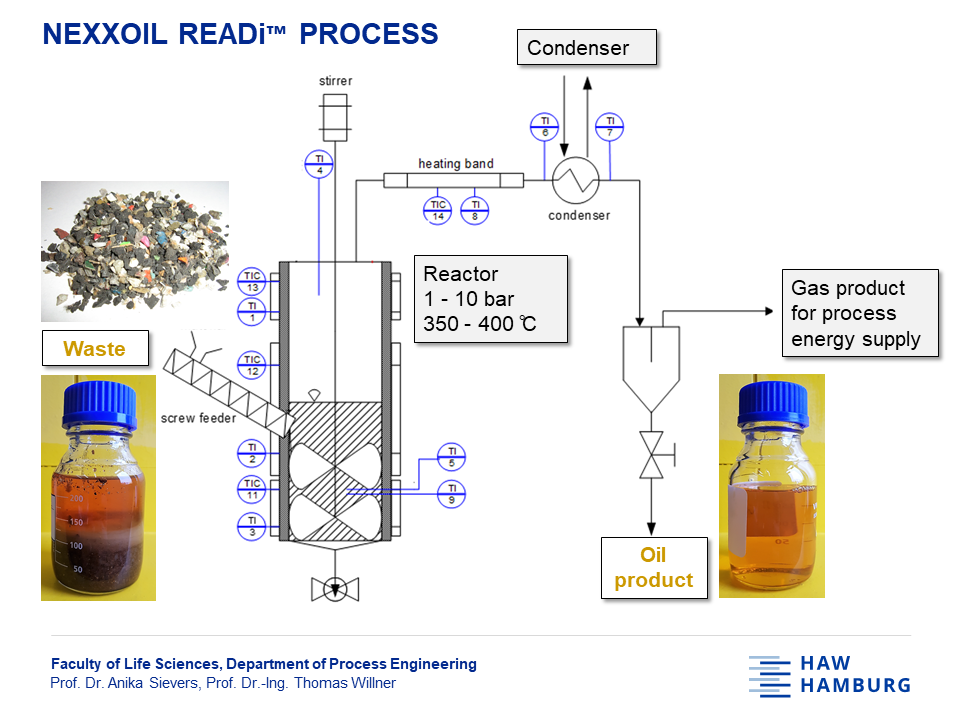

Distillation means the evaporation of the product molecules in the middle and short-chain range which are condensed into the liquid products. In the case of solid feedstocks, the READi process is a variant of solvolytic direct liquefaction. This reaction concept, the so-called reactive distillation has a lot of advantages.

The READi process is operating in fully continuous mode. Due to low conversion temperatures compared to synthesis gas processes high energy efficiency is achieved. More than 70 percent of the primary feedstock energy can be conserved in the oil product. The direct liquefaction process itself needs less than 10 percent of the primary feedstock energy.

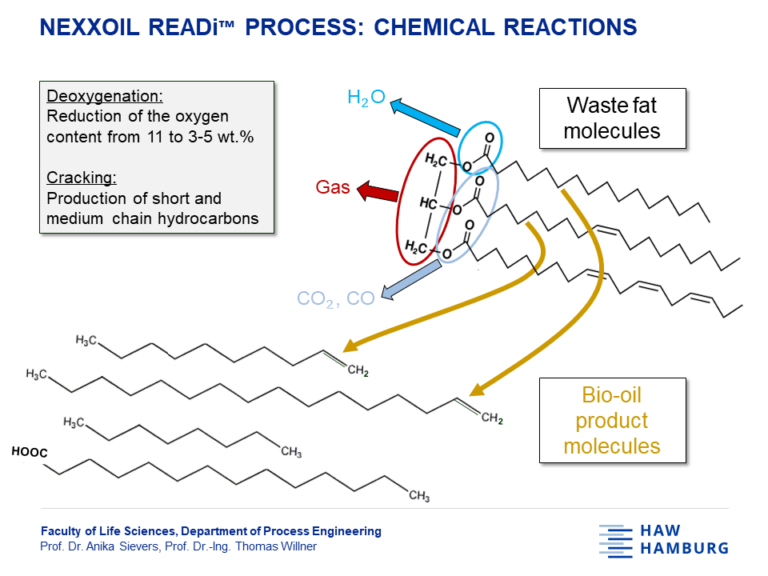

The figure below explains the basic principles in a simplified manner, showing the decomposition of a long-chained hydrocarbon as to find in plastic wastes or comparable materials. This long-chained feedstock is thermally broken down to shorter medium-chained product molecules. These molecules evaporate from the reaction phase and can be collected as a liquid product by condensation.

In the case of oxygen-containing biomass feedstock, the oxygen content is reduced by the formation of water as well as oxygenated gas molecules such as CO and CO2. In a similar way, other heteroatoms such as sulfur and nitrogen can be removed.

High energy efficiency

High energy density oil products

Easy oil upgrading to drop-in fuels

Continuous self-regulated process

Decentralized and robust process set-up

Ambient to low pressures

Moderate temperatures

Removal of heteroatoms such as oxygen, sulfur and nitrogen

Co-production of fertilizers

Zero waste