The READi process is based on solvolytic direct liquefaction of different organic feedstocks in the temperature range between 250 and 500 °C. In the first step, a high-quality light crude oil is produced. NEXXOIL crude oils can be used directly for electric power and/or heat generation or as raw material for the chemical industry. As a further option, the oil can be converted into standard fuel products such as gasoline, diesel and jet fuel by conventional refinery technology.

Due to low conversion temperatures compared to synthesis gas processes high energy efficiency is achieved. More than 70 percent of the primary feedstock energy can be conserved in the crude oil product. The direct liquefaction process itself needs less than 10 percent of the primary feedstock energy.

The minerals of the feedstock can be separated during the conversion process and collected for fertilizer applications.

Among the different approaches of liquefaction, the NEXXOIL process is unique, and has a lot of advantages.

Since more than twenty years READi is under development. Step by step the development team was able to overcome obstacles.

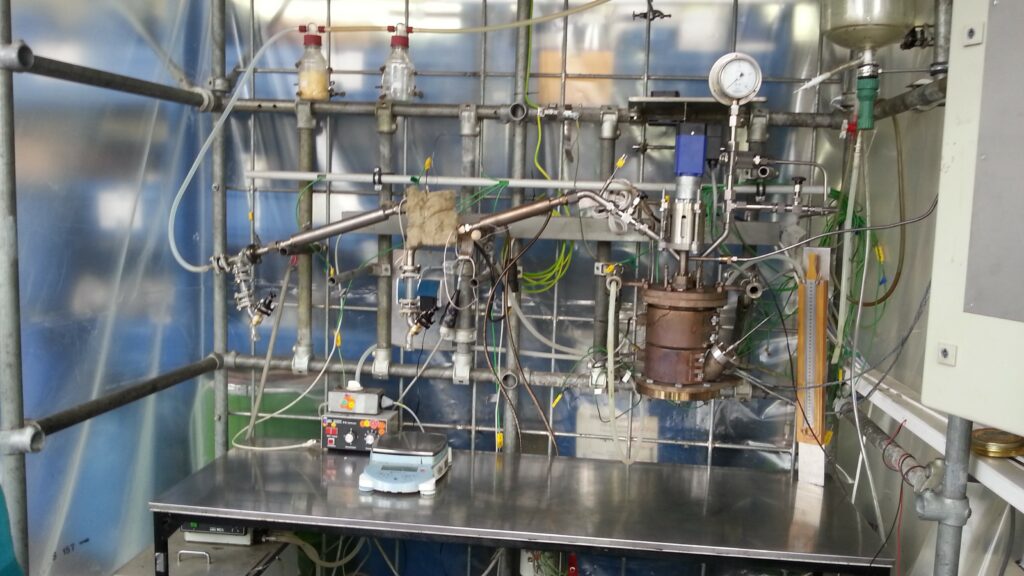

Systems at this scale were used to develop and validate the original technology.

Nexxoil continues to use these systems in its application laboratory to test new waste materials for their suitability as feedstocks in the READi process. the small scale and flexibility of these benchtop systems allow for rapid proof-of-concept validation for new waste-based feedstocks.

This is a highly flexible and automated system, used to optimize and automate the waste-conversion process for a wide variety of feedstocks. This system already integrates a fully computerized industrial control system, which allows this unit to run in automated and continuous mode for hundreds of hours. The 2nd generation system has four times the throughput capacity of our benchtop systems. On the system, processes are developed that can then be ported to our scale-up systems.

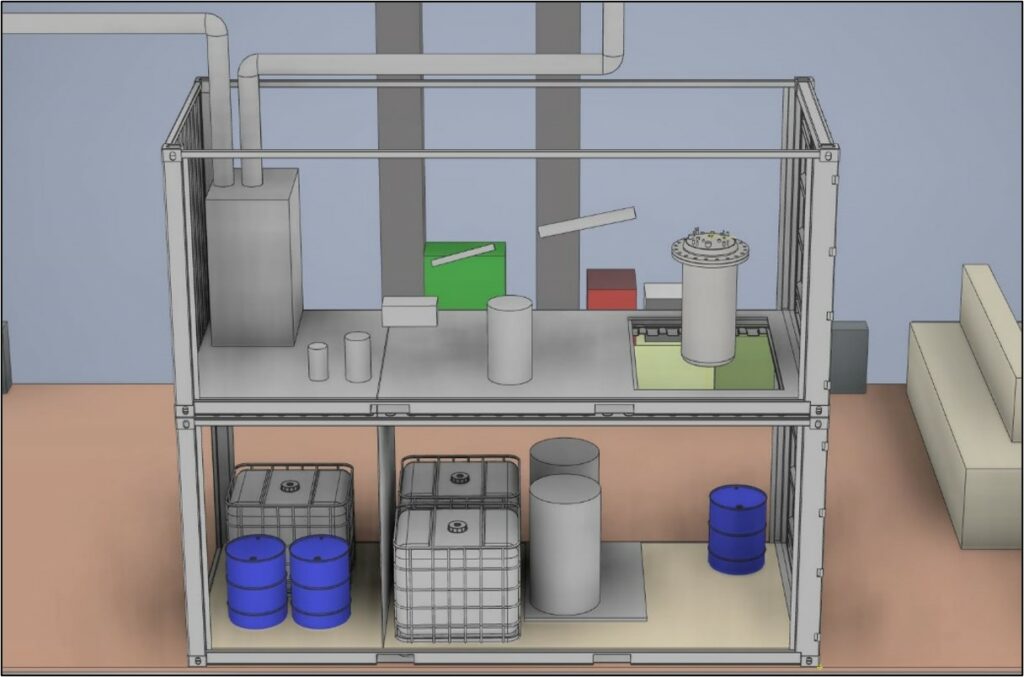

This system represents the next scale-up step with with a production capacity of about 1 ton of product per month. The system is used to validate the scalability of the optimized processes, developed in our smaller units.

This pilot plant, currently under construction, represents the final scale of process optimization and validation before going into production scale. The system is designed to fine-tune and optimize all production process parameters, which can then be transferred to the next scale, which are industrial scale production units. This pilot plant is designed for a monthly product output of up to 10 tons.